- Media reports | Many authoritative media such as Phoenix net, Xinhuanet, Toutiao reported the Jingzhou production base of Shiyu Building Materials

- Publisher: Founder Time: 2023-01-02 12:50:39 Views:0次

Recently, many authoritative media such as Phoenix, Sohu.com, Tencent, Sina.com, Xinhua Newspaper, Zhonghua Net, Business China, Global Fortune Network, Today's headlines, etc."The introduction of new equipment, adding new kinetic energy - Shiyu Building Materials to build digital intelligence "super factory" new engine, reported the measures and achievements of Shiyu Building Materials on the road to the creation of green factories。From the production process, product innovation, brand culture and other enterprise "genes" to share sincerely, the specific content details are as follows。

Screenshot of media coverage (part)

In the context of the increasingly mature technologies such as the Internet of Things, big data and artificial intelligence, a new generation of information technology and manufacturing technology began to deeply integrate, at the same time, with the increase of production equipment, the disappearance of demographic dividend, green manufacturing requirements and other trends, traditional industrial enterprises on the road to intelligent manufacturing has become inevitable。Digital and intelligent advanced equipment is an important sign to measure the scale of enterprise development and modernization level, and it is the only way for enterprises to create new core competitiveness。In order to meet the market demand, to meet the higher requirements of customers。Shiyu Building Materials Jingzhou factory introduced the world's leading gypsum board production line, helping enterprises gypsum building materials production and construction on a new journey, greatly improving the manufacturing efficiency and technical content of Shiyu gypsum board, so that product quality is on a new level。

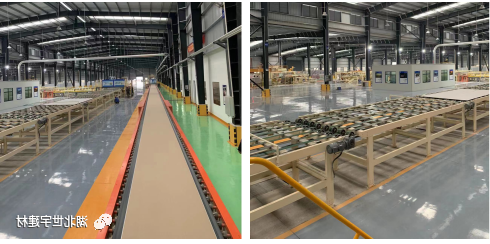

"If a worker wants to do a good job, he must first sharpen his tools.。After a year of intense construction, Shiyu Building Materials Jingzhou factory has been completed and put into operation in October 2022。Into the production workshop, the new online intelligent production line is working methodically。All the main auxiliary materials under the operation of the staff, with the automatic adjustment of the production line speed into the mixing station, just ten minutes to complete the production of gypsum board, finished products into the next process。

1. Equipment upgrade

Build a "number of intelligent" super factory

First-class machinery and equipment are the basic conditions for the production of high-quality products;Digital intelligent equipment is an effective way to improve production efficiency and product quality。Shiyu Building Materials Jingzhou factory is a super factory built in accordance with the world's leading "digital intelligence" standard for gypsum board production。Starting from the warehouse of the reserve of raw materials, the whole process of mechanization does not require manual participation, breaking the island of the traditional production workshop, linking the entire production process into an intelligent assembly line, optimizing the time of each production link, and greatly improving production efficiency。

In production technology,On the one hand, it actively responds to the environmental protection policy of "energy saving and consumption reduction" : the desulfurization and denitrification system of tail gas treatment has been upgraded,Implement ultra-low emission targets of nitrogen oxides less than 50mg/Nm³;Sulfur dioxide less than 35mg/Nm³;Dust particles are less than 5mg/Nm³,It has the advantages of low energy consumption, high efficiency and cost reduction,Make production control more accurate。On the other hand, with the optimization of the production process, the batching system between the board cars has been upgraded from the original dry addition to the wet addition, mainly to reduce environmental dust。The addition of ingredients to the stable molding system ensures the stability of product quality and reduces fluctuations。

Second, process upgrading

Put into "the first automatic packaging line in China"

In recent years, although the industry has been affected by the price of raw materials and the epidemic, the growth rate and market sales of Shiyu Building materials gypsum board still led to the demand for capacity growth and the need for high standard intelligent production equipment。 Therefore, Shiyu Building Materials went against the market and invested hundreds of millions of yuan to build an industry-leading digital intelligence production line。

The product is in the hand, the quality is in the heart, and the details are in the excellence。The current round of upgrading of Shiyu Building Materials Jingzhou factory has been fully implemented in the adjustment of processes and parameters, and it can be said that every detail is a demonstration of quality。The staff at the site told reporters: "We must carefully debug the temperature, pressure, time and other parameters used in each production process every day, record the changes in product quality under different parameters in real time, and finally determine and apply ****** parameters, so that product quality is presented in the best way."。

It is reported that the board car is upgraded from the original two-zone dryer to a three-zone dryer, mainly to reduce the drying temperature of gypsum board, and to standard the product quality of foreign companies, which can well complete the drying curve of gypsum board drying and avoid defects such as over-burning and non-drying。The process has the advantages of environmental protection, energy saving, high thermal efficiency and easy control of process parameters。

At the same time, the finished product packaging system of the workshop has been comprehensively upgraded, and it is currently the first fully automatic packaging line in China, which greatly improves the degree of automation and reduces the labor intensity。

Third, quality management

Strictly abide by the "Three Nos" Principle

Shiyu Building Materials will take the Jingzhou plant into operation as an opportunity,Actively accelerate product development and innovation,Strictly abide by the "do not accept defective products, do not produce defective products, do not release defective products" three principles,Run a full range of quality inspection control systems,Incoming material inspection, process inspection, finished product inspection, factory inspection and laboratory testing are linked together,Responsible for product quality to the end。

The upgrade of the digital intelligence of the Jingzhou factory of Shiyu Building Materials is to maintain the insight of the market demand day after day, is the continuous grinding, updating and iteration, and from the perspective of strategy, technology, products and markets, it is the necessary option to support the rapid and high-quality development of enterprises。In the new era, Shiyu Building Materials actively embrace changes, from production capacity, manufacturing, technology or quality performance are to achieve a full range of upgrades, to provide the market with higher quality products and services, and constantly consolidate the "Shiyu gypsum - China's new first-line high-end gypsum board" brand position。

- Hot keywords: